Fire suppression systems are critical for the safety of people and industrial assets. However, since many fire suppression systems rely on chemical suppression agents, you may be wondering about their environmental impact. On this Earth Day, it is important to highlight the benefits of suppression systems using clean agents. Whether you are looking to protect a CNC machine, a wind turbine, electrical panels, or a data center, clean agent fire suppression systems protect your critical equipment without harming people or the environment.

Understanding Clean Agents

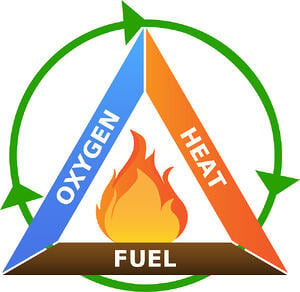

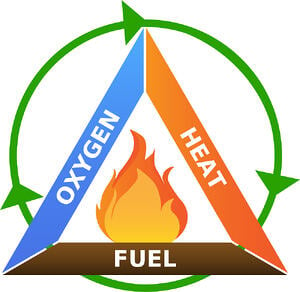

Clean agent fire suppression describes the use of inert gases and chemical agents to suppress a fire. A fire can only occur when three elements are present – a fuel source, heat, and oxygen. This is referred to as the fire triangle. To extinguish a fire, you must block one of the three elements. A clean agent fire suppression system eliminates the heat or oxygen element to break the fire triangle.

Clean agents are nonconductive, noncorrosive, and leave no residue so they will not harm your equipment or your people.

Halon Fire Suppression System Replacement

Up until about 1994, halon was one of the most popular fire suppression agents. Halon efficiently suppresses fires, does not require clean up, and has low toxicity for humans and wildlife. However, research uncovered that Halon, which is a Chlorofluorocarbon (CFC) compound has high Ozone Depletion Potential (ODP). Halon also has a high Global Warming Potential (GWP). Due to their negative impact on the earth’s ozone layer, Halon and other CFC’s became targets for environmental regulations which restricted their use.

Other Environmental Factors

When thinking about clean agents, you may also think of water mist agents as being clean, however, this is a misconception. Water mist contains additives, which may be corrosive or toxic. These agents leave residue and can cause other damage to your critical assets.

Why Go With a Clean Agent Fire suppression System?

The obvious answer is that a clean agent fire suppression system quickly extinguishes the fire without harming the equipment, employees, and the environment. It leaves no residues to clean up which minimizes the disruption to your business operations. Downtime is a substantial cost to a business and can lead to lost revenue, dissatisfied customers, and damage to your brand reputation.

Common Applications for Clean Agents

While all suppression agents have advantages and disadvantages, it is most important to understand your application requirements to select the appropriate agent. In particular, clean agents are recommended for a wide variety of microenvironments and facilities with sensitive equipment. From CNC machines to electrical panels to telecommunications and server rooms, these applications are all great examples of where it makes sense to use clean agents in your automatic fire suppression systems.

The Clean in Clean Agents

The “clean” in clean agent fire suppression systems means the agents are safe to use in areas where humans reside. They do not contain any substance that is toxic or harmful. When determining what fire suppression agent to use, consider all of the factors including the equipment you are protecting, the class of fire the agent will suppress, and the health and environmental impacts of the suppression agent.